Gerry McDonnell

Archaeometallurgy

There is extensive literature on the metallurgy of iron and steel dating back to Percy’s texts of the 1860’s. The definitive text on the iron-carbon phase diagram was by ***** in only 19**. The most comprehensive recent text is Samuel’s “Light Microscopy of Carbon Steels”.

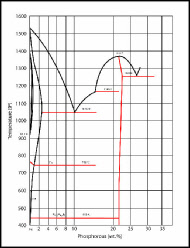

However, modern metallurgy is based on high quality control, e.g. of carbon content and cooling rates. This is in stark contrast to archeological and historical iron artefacts which are characterised by varying composition (principally of carbon and phosphorus), variations in thickness and cooling rates, as well as multiple heating and cooling cycles.

The manufacturing typology of archaeological/historical iron artefacts can be sub-divided into three main types:

Single Alloy - artefacts manufactured from one alloy, e.g. Ferritic iron, phosphoric iron etc...

Heterogeneous Iron - artefacts manufactured from naturally banded iron.

Composite Artefacts - artefacts deliberately manufactured from two or more bars of different composition, e.g. Type 2 knives with a steel edge welded to a ferritic/phosphoric/heterogeneous iron back.